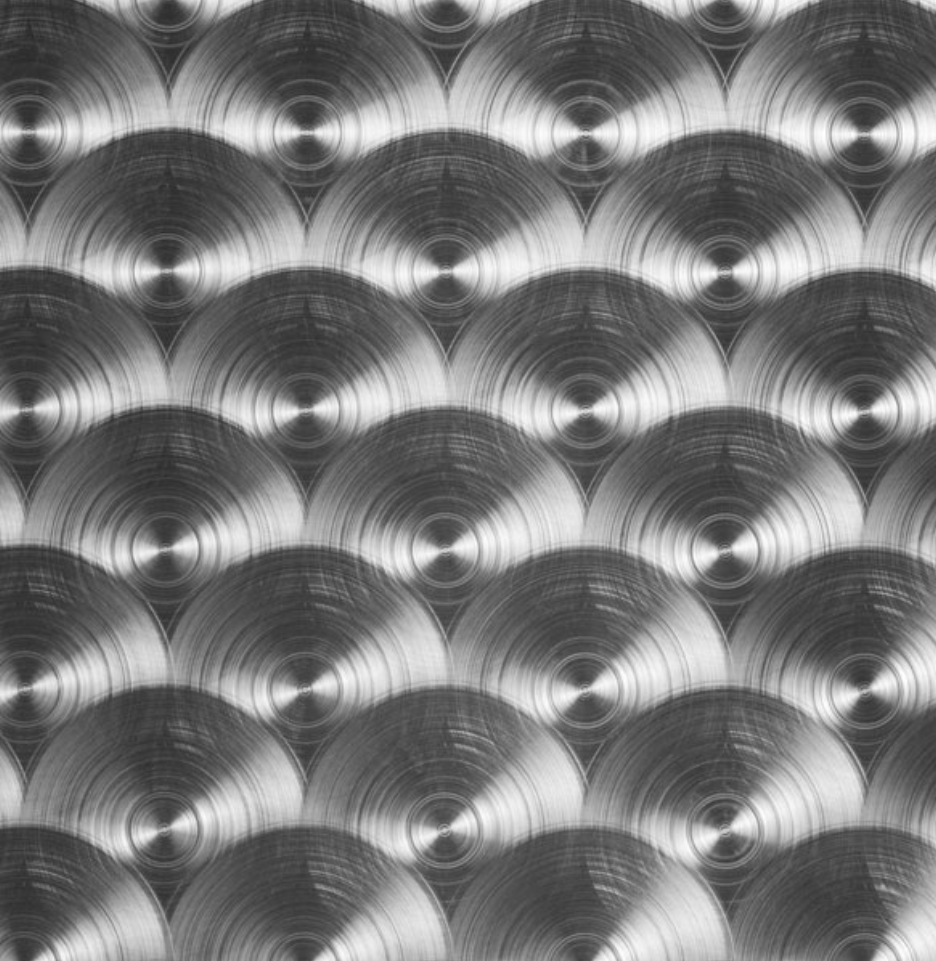

Embellishing

One of the most particular and most requested types of stainless steel processing

This particular effect is obtained by sanding the sheet with staggered rotating pads with a constant pitch,

usually at 60 °. You can also create special patterns and designs, using special machinery called Flowers.

The embellisment machines perform, on sheets of various materials, the particular circular overlapping and

crossed polishing finish called precisely embellishments, or rosettatura, or damask, or marbling. It is also

possible to have another finish, of longitudinal strips grinding, called “in bands”.

The flowers are built in different versions; Rollers, Feeder, Combi, and Bench, which differ mainly in the way

of handling the sheet, intermittent for the series A Rollers and Feeder, continuous for the Combi series, and

without movement of the sheet for the A Bench series . Common basis for all versions are the Flowering

Units. These have working widths of 250mm or 500mm, which combined with each other, using or excluding

two to more units, allow to obtain working widths equal to the standard sizes of the sheets of 1000, 1250,

1500, 2000mm. The spacing of the spindles can be 60mm or 50mm, to which wheels of diameters 60, 50,

40, 30mm can be mounted.

The A Rollers and Combi series also have the possibility of operating as a protective film spreading machine,

both at the same time as flowering and only as a sheet laminator.These versions are equipped with a

suction hood for cleaning the sheet metal before applying the protective film. Each machine can work with or without loading and unloading roller conveyors, it can be equipped with sheet handling systems, automatic

film cutting, suction and ventilation systems for cleaning and cooling the sheet.

Rollfilm

In combination with the embellishment, the film drying module allows to apply a special adhesive protective film on the visible side of the flat sheets, identifiable according to the various microns of adhesion so as to guarantee during the subsequent processing phases both cold and cut, the goodness of the surface of the product that will be made.

No products in the cart.

No products in the cart.